HOW TO PROPERLY MAINTAIN A NITROGEN GENERATOR

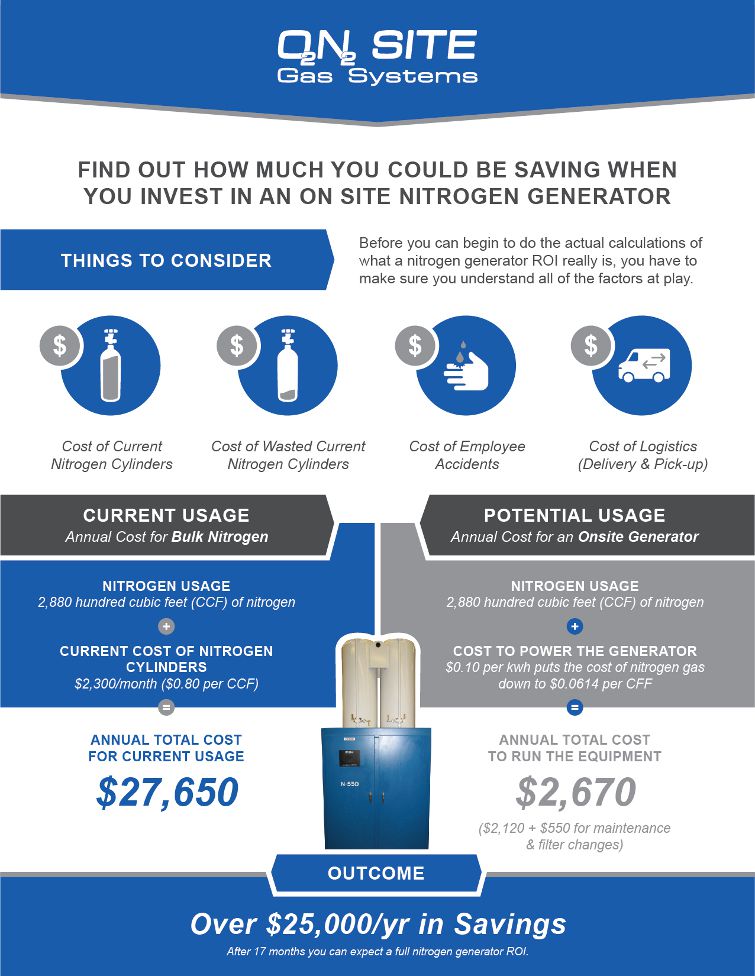

It is our priority to provide clients with high-quality, world-class nitrogen generating systems with proper care and maintenance services. Nitrogen generators are a cost-effective solution when compared to other systems, and when cared for, can continue producing nitrogen with accuracy and efficiency for decades.

Regular maintenance and upkeep should always be performed to ensure your generator is working correctly. Our experienced technicians at On Site Gas understand that completing basic upkeep on your nitrogen generating system is necessary. That is why we incorporate several easy procedures into our process that will help enhance the lifespan of your product. Following these six steps will help keep your nitrogen generator system functioning for as long as possible:

1. Keep the Equipment Clean

The first step to maintaining your nitrogen generator is always keeping it clean. Use a damp cloth to clean all parts carefully. While doing so, make sure to avoid contact with the nitrogen generator system’s electrical components.

2. Check Status Gauges and Indicators

There is a control panel visible on the front of nitrogen generators. Check the status of both the gauges and indicators to confirm the nitrogen generating system is functioning as it should. Ensure the system has no leaks and look over the quality of the inlet air, too.

3. Shut the Nitrogen Generator Down After Use

Follow the guidelines in your nitrogen generating system’s maintenance manual to properly shut the unit down after every use. This will help improve your nitrogen generator’s lifespan.

4. Regularly Change the System’s Filters

Many nitrogen generator systems use a combination of carbon and coalescing filtration. Carefully look at the instructions in your nitrogen generator system’s manual to change these filters and discard elements according to the waste disposal procedures utilized by your company.

5. Restart the Nitrogen Generating System

After changing the filters, restart the equipment. Again, check your nitrogen generator system’s manual to ensure you follow the proper start-up procedure.

6. Replace Your Oxygen Sensor and Valve

Typically, your nitrogen generator’s oxygen sensor needs to be replaced every three years. The frequency in which you change it will depend on the number of hours the nitrogen generator is in use. We recommend that an experienced service technician from On Site Gas perform this procedure for you.

Choose On Site Gas For Your System’s Maintenance Needs

Our nitrogen gas generating systems are used all over the world. There are many reasons why companies choose equipment such as pressure swing adsorption (PSA) nitrogen generators. One being more cost-effective than other systems while allowing you continuous access and a steady supply of your gas without a delivery contract. Systems including nitrogen membrane generators also employ energy-saving tactics, eliminate the need for potentially hazardous cryogenic liquids, and are an overall more versatile option than other delivery systems.

The experts at On Site Gas are always ready to answer any questions about maintaining your nitrogen generating system. Contact us today to learn more about what we do or purchasing refurbished generators.