Advantages of Using a PSA Nitrogen Generator in Various Industries

Pressure swing adsorption nitrogen generators, also known as PSA nitrogen generators, can produce a high-purity supply of nitrogen. Requiring only a power source and the air around us, these generators are able to produce a continuous supply of nitrogen for businesses in multiple industries.

PSA nitrogen gas generators are a must-have product for companies in the food and beverage industries, pharmaceuticals, chemicals, automotive, oil and gas, aeronautics industry, and more. If you own a company in one of these industries and do not have a PSA nitrogen gas generator, you may be relying on nitrogen cylinder delivery for your supply of nitrogen. These cylinders are impractical, unreliable, and have negative environmental consequences.

It’s important to use the best tools at your disposal for your business, and this is why many companies turn to PSA nitrogen generators. PSA nitrogen generators are reliable, consistent, have low operating costs, and are less damaging to the environment.

Understanding PSA Nitrogen Generators

What is PSA Technology?

A PSA nitrogen generator is a device that produces high-purity nitrogen from air. The generator starts by removing impurities. Next, the nitrogen is adsorbed by material in the generator, while other gasses are discharged back into the air. Nitrogen is then desorbed and ejected through the outlet. This process happens over and over again, allowing operators to cull nitrogen from the air.

Key Components of PSA Nitrogen Generators

PSA nitrogen generators are made up of several components, including:

- Air compressor

- Air dryer

- Twin towers PSA Nitrogen Generator with Carbon Molecular Sieve

- Storage tank

- Control panels

The PSA nitrogen generator consists of two towers that do the same thing. While one tower is desorbing, the next one is adsorbing, to produce a continuous supply of nitrogen.

General Benefits of PSA Nitrogen Generators

There are many reasons that businesses choose PSA nitrogen generators over other sources of nitrogen. Below are some of the general benefits of PSA nitrogen generators.

Cost Efficiency

Running a PSA nitrogen generator to produce nitrogen costs less than purchasing a regular supply of nitrogen through cylinders and other delivery methods. Although PSA nitrogen generators cost more upfront, most businesses see long-term savings and quick return on investment (ROI) with this type of purchase.

On-Demand Nitrogen Supply

PSA nitrogen generators are flexible and convenient. They can produce a continuous supply of nitrogen seven days per week, and they eliminate dependency on external nitrogen suppliers.

High Purity and Consistency

Nitrogen generators are a reliable source of high-purity nitrogen. High purity levels are important for various industrial applications.

Environmental Benefits

Whereas nitrogen cylinders are delivered by trucks to businesses, nitrogen generators stay in one spot and use only a little electricity to do their job. Businesses that switch to nitrogen cylinders see a reduction in their carbon footprint by eliminating transportation of nitrogen cylinders. Nitrogen cylinders also use an energy-efficient operation, thus switching to this type of cylinder can have a positive impact on the environment.

Industry-Specific Advantages of PSA Nitrogen Generators

Below are some of the industries where nitrogen generators are most often used. If your business is dependent upon nitrogen delivery to operate, whether your industry is listed below or not, you too may be able to benefit from a nitrogen generator.

Food and Beverage Industry

In the food and beverage industry, nitrogen is used for packaging and preservation. Presence of nitrogen and lack of oxygen in packaging prevents oxidation, which can cause the development of off-odors and flavors. MAP packaging (modified air packaging), which replaces oxygen with nitrogen in food packages, is essential to ensure the long shelf life of packaged foods.

Pharmaceutical and Chemical Industry

Nitrogen is an inert gas, so it doesn’t react with chemicals and products like medications. In the pharmaceutical and chemical industries, nitrogen is used to create inert atmospheres to prevent oxidation. Just like in the food and beverage industries, nitrogen is used to flush out the air in packages that contain chemicals and medications. This helps ensure a long shelf life of the product.

Electronics and Semiconductor Industry

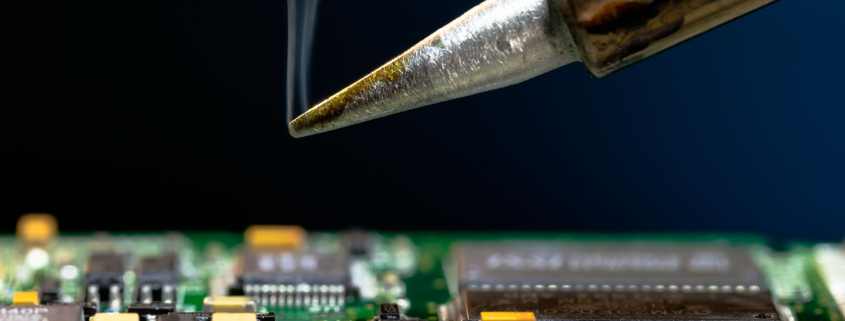

Oxidation can cause deterioration and poor quality in solder joints, just as it can produce deterioration in food and beverages. This happens because oxygen reacts with solder to create an oxide layer during the soldering process.

Nitrogen is used to replace oxygen during soldering, wave soldering, and component assembly to ensure quality and reliability in electronics manufacturing. This prevents oxidation and ensures high-quality solder joints in electronics and semiconductor manufacturing.

Automotive and Aerospace Industry

Oxygen has a way of passing through tire rubber over time, which can lead to deflation of tires. Nitrogen does not pass through rubber, and thus nitrogen can be used in tire inflation in automobiles and airplanes.

Nitrogen can also be used in fuel inserting systems, which reduce the amount of oxygen in fuel tanks to prevent the possibility of combustion. Nitrogen’s inert properties improve fuel tank safety.

Oil and Gas Industry

Nitrogen’s inert qualities come in handy in the oil and gas industry. Nitrogen is used in pipelines in well drilling because it’s non-combustible. Removing nitrogen from pipelines helps create a safe work environment and prevent accidents in the industry.

Nitrogen is also used to purge pipelines of oxygen and pressure test pipelines to check for leaks. In fact, Nitrogen’s inert properties make it safer to use in these instances.

Why Your Industry Needs PSA Nitrogen Generator Technology

Nitrogen is a useful gas in many industries. It is stable, inert, and abundantly found in the Earth’s atmosphere. Many businesses use nitrogen for preservation of products and to prevent oxidation. Nitrogen can also be used to reduce risk in normally flammable environments.

PSA nitrogen generators are efficient machines that can be used to produce nitrogen easily and in a cost-effective way. For businesses that prioritize environmental responsibility, nitrogen generators can help reduce the size of their carbon footprint while improving operational flexibility.

If your business relies on nitrogen for your product packaging, manufacturing or industrial processes, a nitrogen generator can be a valuable investment. To enhance your industrial processes with a PSA nitrogen generator, contact On Site Gas today.

Leave a Reply

Want to join the discussion?Feel free to contribute!