Choosing the Right PSA Nitrogen Gas Generator for Your Specific Application

Nitrogen gas is an in-demand product used in a variety of industries, from food packaging to steel production. In many industries, nitrogen is used to prevent products from spoiling, thus allowing food and medications to be stored longer and transported long distances. This makes nitrogen very important to our global supply chain, and an important material for many companies. Nitrogen is present in the air we breathe, but capturing nitrogen for use in manufacturing industries requires special equipment.

If you’re a business that uses nitrogen in its day-to-day manufacturing, it’s important to find the right type of nitrogen generator for your business. The best generators will efficiently produce enough nitrogen for your needs, at the purity level that you require.

Unlike cylinders or liquid nitrogen, PSA nitrogen generators are cost-effective and relatively low-maintenance. There are many benefits of quality nitrogen generators. Here’s what you need to know.

What Is a PSA Nitrogen Generator?

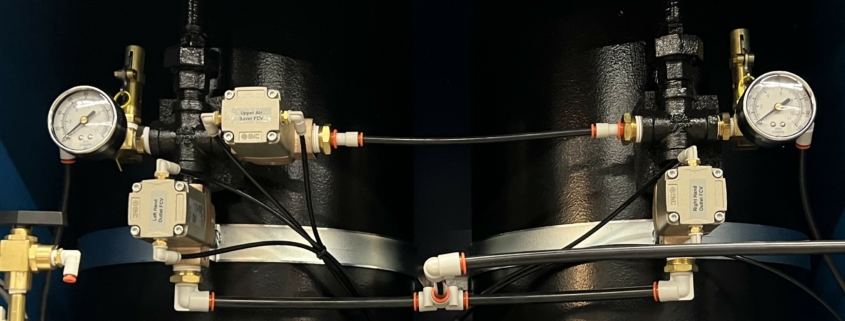

PSA stands for pressure swing adsorption. A PSA nitrogen generator is a device that produces nitrogen through a process that starts when compressed air is filtered to move impurities like oil and moisture. Once the air has been filtered in this way, it is passed to adsorption vessels with a special sieve that can adsorb any remaining carbon dioxide, moisture, and oxygen. Once this is done, the filtered nitrogen is produced at the desired purity, while any remaining oxygen is vented back into the atmosphere.

What Is a Membrane Nitrogen Generator?

A membrane nitrogen generator works by pushing compressed air through polymer fibers. As the compressed air moves through the fibers, the nitrogen molecules are separated from the other molecules in the air. Through this process, nitrogen is produced at the desired purity. While any remaining oxygen is vented back into the atmosphere.

PSA vs. Membrane

PSA and Membrane nitrogen generators are both similar but very different devices, so it’s important to understand those differences when trying to determine which type of generator is right for your business.

PSA Generator Purity Levels

Nitrogen purity is an important factor when trying to choose between two different types of generators. PSA nitrogen generators can provide nitrogen at a higher purity than membrane nitrogen generators. In fact, PSA generators from On Site Gas can produce nitrogen at a purity level of up to 99.9995%, depending on your needs. Knowing the purity level that’s required for your manufacturing process is important when trying to decide which type of generator is right for you, so have this information before you start shopping for a generator manufacturer.

PSA Generator Consistency

PSA nitrogen generators can reliably produce the nitrogen gas at the high purity level required. In industries where a consistent high purity level is required, PSA generators are the best product.

PSA Generator Durability and Maintenance

PSA nitrogen generators have few moving parts, so they’re long-lasting and require little maintenance. Many of On Site Gas’s PSA nitrogen generators last for twenty years or more before needing replacement. The sieve material that is used in the PSA process can last for decades with minimum maintenance.

Membrane Generator Purity Levels

Membrane generators from On Site Gas can produce nitrogen with a purity level between 95% and 99.9%. Talk to your representative from On Site Gas to tell them the purity level that you require.

Membrane Generator Durability and Longevity

Membrane generators have no moving parts, which makes them easy to maintain and easy to repair if needed. Membrane generators made from On Site Gas last for many years.

Why PSA or Membrane Nitrogen Generators?

PSA or Membrane nitrogen generators from On Site Gas are preferred by many businesses for nitrogen delivery. There are many reasons for this, including energy savings, cost savings, safety, and versatility.

Energy savings. On Site Gas PSA or Membrane nitrogen generators go into standby mode when not in use, as pressure monitors within the system continue to create just enough pressure to ensure nitrogen generation is quick and efficient when nitrogen generation begins.

Cost savings. PSA or Membrane nitrogen generators are a budget-friendly option for businesses that need an affordable supply of nitrogen. PSA or Membrane nitrogen generators are much more affordable than cylinder delivery or liquid delivery of nitrogen.

Safety. Nitrogen generators are safer than high-pressure cylinders full of gaseous nitrogen, and cryogenic liquids full of very cold nitrogen. Nitrogen generators are stable, easy to use, and produce a steady supply of nitrogen when needed.

Versatility. PSA or Membrane nitrogen generators are highly versatile and can be used for applications across industries ranging from electronic manufacturing to food packaging to laser cutting. On Site Gas has created nitrogen generators that provide the quantity, purity, and flow of nitrogen that you require.

How To Choose The Best Nitrogen Generator For Your Needs

Choosing the best nitrogen generator for your business can be a challenge. There are many variables to consider including cost, generator maintenance, purity levels, and more. The best way to find the nitrogen generator that’s right for your business is to work with one of the most respected PSA and Membrane nitrogen generator manufacturer businesses in the country. Contact a customer service representative with On Site Gas Systems.

We design custom nitrogen generator systems, to ensure that our customers get the right type of nitrogen generator for their business needs. Want to know more about how you can get a nitrogen generator with On Site Gas Systems? Contact us for a consultation. As one of the leading PSA nitrogen generator manufacturers, we can help you find the right nitrogen generator for you.

Leave a Reply

Want to join the discussion?Feel free to contribute!