How Does an Oxygen Generator Work?

Many industries need high purity oxygen for their manufacturing needs. Getting oxygen gas can be expensive and impractical without a dedicated oxygen generator. Knowing how an oxygen generator works can help you decide if this type of generator is right for you.

What is an Oxygen Generator?

An oxygen generator is an application that uses a unique selective adsorption technology to separate the oxygen from the nitrogen and other components in compressed air. The oxygen can flow through sieve that retains any nitrogen, producing high purity oxygen.

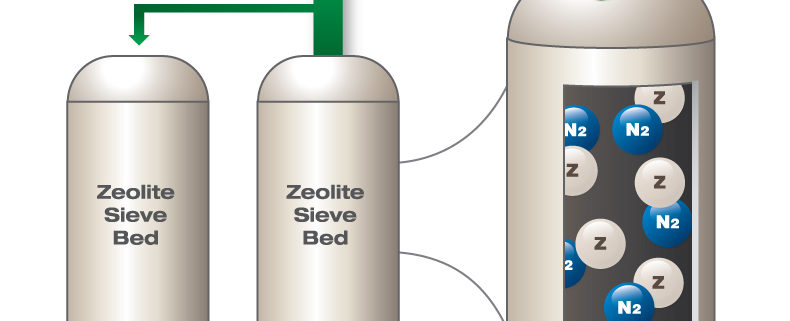

Oxygen generators are very similar to nitrogen generators. One way that oxygen generators are different is the material inside the sieve is made from zeolite instead of carbon.

Air channeled through the oxygen generator is separated into the gasses that make up the air. The sieve selectively absorbs the nitrogen with the zeolite, thus allowing the high purity oxygen to flow through the generator and be used in an application, or stored in tanks as needed.

What Are Oxygen Generators Used for?

Various applications can use an oxygen generator, including medical, sewage and wastewater treatment, paper making, food and beverage industries, glass manufacturing, mining, commercial fish farming, metallurgy, gasification processes, and more.

How Do Oxygen Generation Systems Work?

So, how do oxygen generators work? The generator uses an adsorptive tower with zeolite to retain nitrogen while allowing oxygen to pass into a collecting tank. The generator continues functioning until the zeolite sieve has reached full saturation and can no longer absorb nitrogen.

Once the zeolite has fully absorbed as much nitrogen as it can handle, the cylinder is depressurized to release the nitrogen into the atmosphere. This process is regulated by a unit that detects oxygen and nitrogen gas saturation levels.

Oxygen Generator vs. Oxygen Concentrator

The terms oxygen generator and an oxygen concentrator are often used interchangeably, and in general, these terms mean the same thing. Often, the term oxygen concentrator is used to describe a smaller, more portable oxygen generator, while the term oxygen generator is used to describe a large device that produces large quantities of oxygen for industrial use.

What Parts Make Up an Oxygen Generator?

Oxygen generators are generally made up of the following pieces:

- Particulate and coalescing filters

- Air compression unit

- Zeolite sieve

- Air dryers

- Single pressure stabilizing reservoir

- Gas circulation tubing

- Inlet and outlet valves

Contact On Site Gas Systems

Oxygen generation isn’t a simple process, so you may still question how oxygen generators work. On Site Gas Systems make and install oxygen generation systems for companies worldwide. If you still have questions about how oxygen generators work or want to learn more about our products and processes, or whether or not an oxygen generation system is right for you, we’d be happy to help. Contact us today!

Leave a Reply

Want to join the discussion?Feel free to contribute!