Nitrogen Generation for Injection Molding

Most injection molders require 99% nitrogen (N2) for their applications. Nitrogen membrane generator systems are effective to approximately 99%, while the PSA nitrogen generator system generates N2 gas up to 99.9995% and is more effective in many applications. The process of injection molding in manufacturing is a particular method that makes parts in large quantities. Otherwise known as mass-production, the same amount is produced the same way millions of times in a row. Injection molding is widely spread, specifically in the plastics industry.

Nitrogen Systems for Injection Molding

Injection molding is elemental to making different kinds of parts, including:

- Automotive parts:

- Intake manifolds

- Dashboard knobs and switches

- Medical components:

- Surgical devices

- Syringes

- Other elements:

- Electrical circuit boards

- Toys

- Bottle caps

- Jewelry boxes

Plastics can overmold metal components, too. Some examples of this include plastic handles for hammers or screwdrivers. There are four main steps to the injection molding process:

- Clamping

- Injection

- Cooling

- Ejection

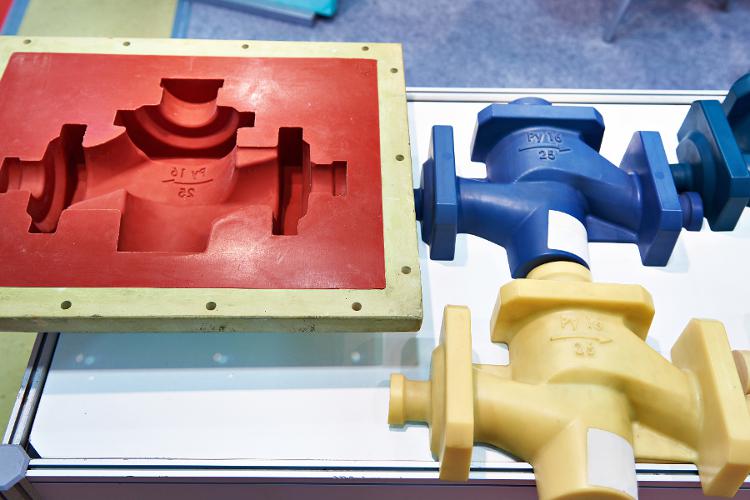

Essentially, plastic in the form of pellets, or granules, is pumped into the molding machine. The plastic granules are heated until melted into a liquid. The nozzle of the apparatus injects the liquid plastic into the cavity of the mold. Once cooled, the component is finished and ejected from the mold. Any oxygen that may enter the process can compromise the finished product with blemishes or even weaken it.

Nitrogen generation is an affordable and effective way of eliminating oxygen throughout the injection molding process. Nitrogen is used as both a propellant and removes moisture and oxygen from getting into the processing system. Using a nitrogen generator on-site eliminates defects and blemishes from the final product and saves money in production.

With thirty years of nitrogen generation expertise, On Site Gas Systems can configure a superior nitrogen generator for your injection molding needs. To learn more about our nitrogen generation systems, contact us today.